The acronym CAPI stands for Cut, Abrasion, Puncture, and Impact, and represent the primary forms of protection covered in the ANSI standards and the baseline classification of all types of safety gloves.

Keeping these standards in mind will help you guard against the majority of hand injury threats across a variety of industries such as construction, manufacturing, fabrication, warehousing, and basically every other form of hands-on work.

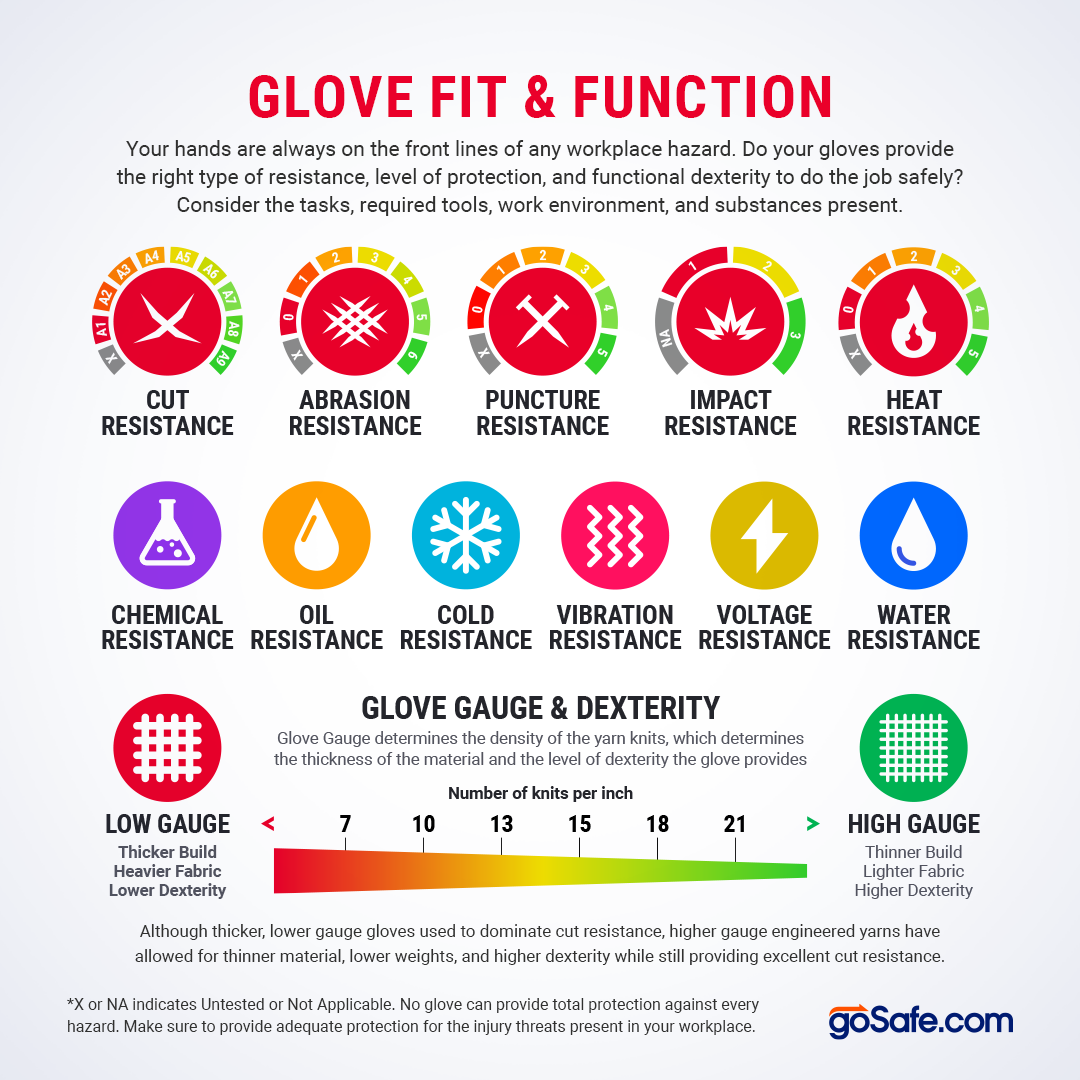

Each of the scales shown here demonstrate ascending levels of protection from different forms of contact. When selecting a glove make sure that you have the proper level of protection for your specific job across all potential levels of hazardous contact.

SAFETY GLOVES CHEAT SHEETS

Your hands are at the front lines of every task you do, so when it involves heavy labor, industrial work, dangerous materials or hazardous substances, you absolutely need to protect them. But the particular kind of gloves is key, and while there are specified standards for cut, abrasion, puncture, impact, and heat resistance, there may be other factors to consider, including dexterity, environmental considerations, and types of coatings.

So to make this easier, here are some infographics for quick reference on standards and best practices for a variety of use cases. Click or tap each image for full size.

THE PERFECT FIT FOR FUNCTION

What are your workers handling? Sharp Objects? Chemicals? Small Nuts and Bolts? Power Tools? Oils or Liquids?

Where are they working? A Construction Site? A Lab? A Forge? Is It Cold?

What substances are present? Hot Steam? Molten Metals? Chemicals? High Voltage?

All of these must be considered to ensure proper safety in all present or potential conditions:

- Chemical Resistance: Helps prevent hand contact to toxic, dangerous, or reactive chemicals.

- Oil Resistance: Helps prevent loss of grip and tool slippage in oily environments, essential to preventing accidents from dropped tools or over extension.

- Cold Resistance: Prevents numbness and frostbite in cold environments and winter months.

- Vibration Resistance: Helps prevent nerve, blood vessel, muscle, bone, and joint damage from high-frequency vibrations from power tools such as grinders, saws, and sanders in combination with proper pacing and breaks.

- Voltage Resistance: Helps prevent electrical shock from high voltage wiring and electrical current.

- Water Resistance: Extends the life of the glove and may keep hands dry in wet work, high humidity, coastal, and rainy environments.

Also worth considering is dexterity: which improves hand mobility and helps the worker maintain grip on tools or small objects, preventing dropped object accidents and hand injury.

The key factor in dexterity is Glove Gauge, which tells you the number of knits per inch. Although you might think a high glove gauge would lead to a thicker glove, the opposite is actually true. This is because smaller knits requires thinner threads, which also lowers the weight of a glove, improving comfort and dexterity.

Pair this with engineered fabrics and you now have cut, abrasion, and puncture resistant materials that no longer compromise dexterity, providing the best all-around injury prevention for general labor.

THE RIGHT COATING MAKES THE DIFFERENCE

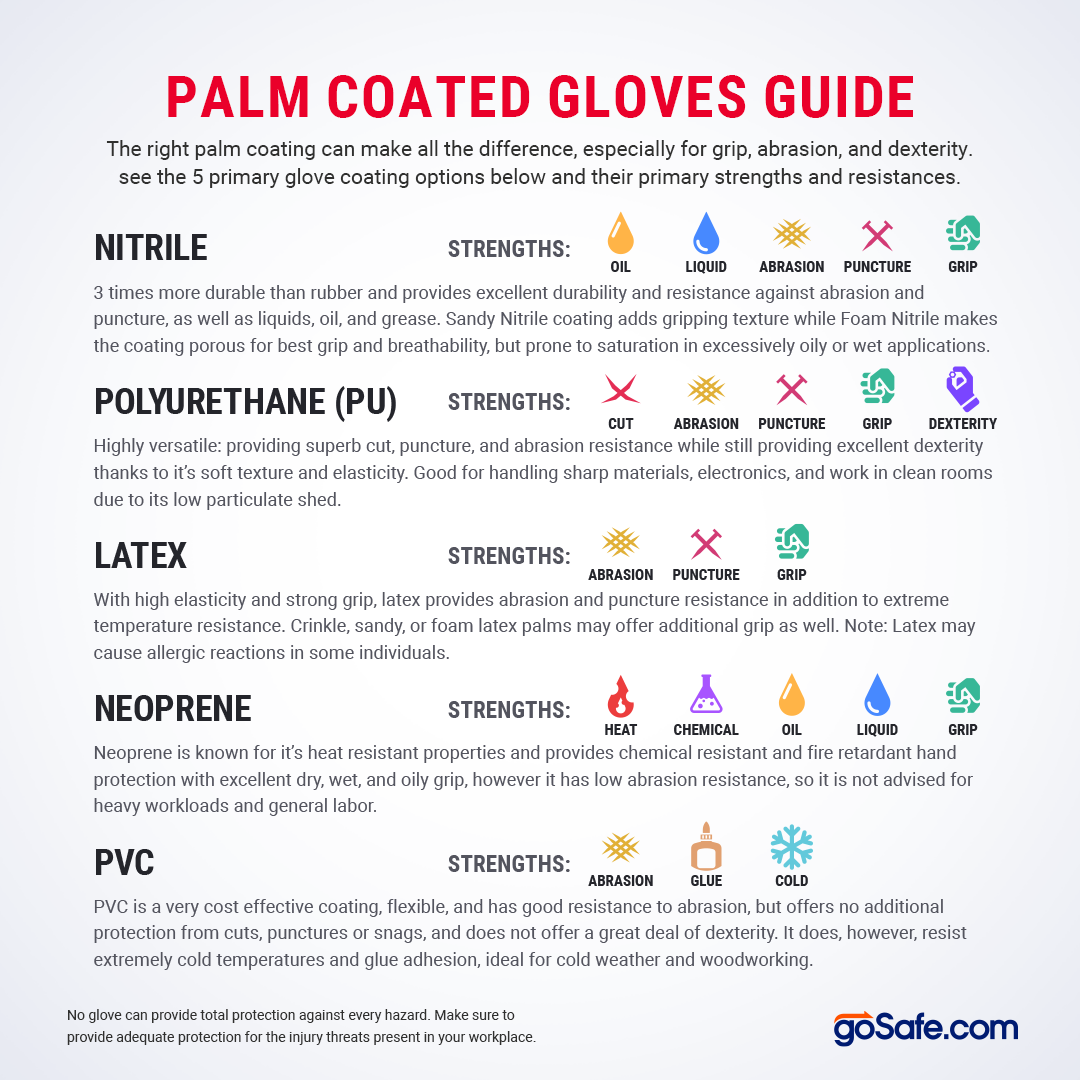

Some glove materials may offer a good deal of base level protection, but when it comes to grip and oil, liquid, heat, or cold resistance, it's often dependent on the coating.

Palm coatings offer an additional level of protection against a variety of hazards as well as secondary accidents from lost grip. To help you choose the right glove for the job, here are some key factors and strengths for the top 5 forms of glove coatings. Some of these coatings are more common as full coated gloves for specific applications, but if that's your worksite, then you'll need every ounce of protection you can get.

MAXIMIZE YOUR BUDGET

Choosing the right glove is a balance between protection, ease of use, and cost value. Even though it's tempting to go for the higher safety ratings, that can sometimes prove not as effective when a lower rating is all that's needed, and may even restrict the user's hands by being thicker and less dexterous.

Meanwhile choosing the cheapest gloves you can find may also lead to unintended consequences. In fact, many cheap glove manufacturers have been known to falsify protection ratings, claiming certified ANSI level protection when they haven't been properly tested by a 3rd party.

To make matters worse, many gloves are simply thrown away or go unused either because they become dirty or workers are not properly trained on their use.

All of these pitfalls, in addition to other factors, can lead to a loss in protection as well as unintended costs.

goSafe's Blog Articles on this topic

- Cut Protection 101: Understanding the Basics

- Understanding Palm Coatings

- Guarding Your Grips: Why Abrasion Resistance is Key to Industrial Glove Selection

- Understanding Puncture Resistance in Industrial Gloves: A Comprehensive Guide

- Don't Get Sidelined: Choosing the Right Impact-Resistant Gloves for Your Job

- Hand Safety: Finding the Perfect Fit & Function in Industrial Gloves

- Hand Protection That Doesn't Break the Bank: Choosing Cost-Effective Industrial Gloves