When will a Personal Fall Arrest System (such as a davit mounted SRL) or Ladder Safety System (engineered cable/rail system) be required on a fixed ladder?

In 2016, OSHA 1910 was updated. With this update, the previous requirements and standards for fixed ladders with cages are phasing out in favor of Personal Fall Arrest Systems (PFAS) and Ladder Safety Systems. OSHA 1910.28(b)(9) lays out the new requirements regarding both new and existing fixed ladders, PFAS and ladder safety systems, and the related compliance deadlines.

The new regulations went into effect on November 19, 2018. They require specific measures of protection for any fixed ladder extending more than 24 feet above a lower level. Under this new regulation:

- Any ladder installed before that date must have a PFAS, cage, ladder safety system, or well. 1910.28(b)(9)(i)(A)

- Any ladder installed on or after that date must have a personal fall arrest system or a ladder safety system installed. 1910.28(b)(9)(i)(B)

This means that any fixed ladder installed ON or AFTER November 19, 2018 that utilizes a cage or well and does NOT have a ladder safety system or PFAS installed, will NOT comply with current OSHA requirements. In addition, "When a fixed ladder, cage, or well, or any portion of a section thereof is replaced, a personal fall arrest system or ladder safety system must be installed in at least that section of the fixed ladder, cage, or well where the replacement is located." (1910.28(b)(9)(i)(C)).

November 18, 2036 is the final deadline for all existing fixed ladders to be brought into compliance with the new OSHA regulations. "On this date, all fixed ladders must have an attached PFAS or ladder safety system." 1910.28(b)(9)(i)(D). At this time, any fixed ladder using only a well or cage will be considered non-compliant by OSHA. Interestingly enough, existing cages or wells may remain in place as long as they don’t interfere with the required safety systems.

How do I choose the correct Full Body Harness?

Choosing the correct harness requires careful consideration of several factors. As you have probably seen, Full Body Harnesses come in a wide variety of configurations and are constructed from different materials and may also have very specific features.

Let us first consider the D-ring configuration as the primary decision-point. Generally speaking, this determines the suitability of the Full Body Harness (FBH) for the various fall protection applications (see “What are the ABCD’s of fall protection?” for additional information). Typical D-ring locations and their intended purposes are described below:

- Dorsal D-ring (Back D-ring): Located on the wearer’s back, centered between the shoulder blades, this location is universally appropriate for fall arrest as well as for restraint.

- Hip D-rings: Located on, or directly adjacent to the wearer’s hips, this pair of D-rings is intended to support the weight of the user while engaged in work-positioning.

- Sternal D-ring: Located on the wearer’s sternum, in the center of the chest, this D-ring is intended to create an attachment point for use on ladder climbing systems or fall arrest systems wherein free-fall is limited to two feet or less.

- Frontal D-ring: Typically located at, or slightly above the belt-buckle, this is an attachment point for use in rappelling applications.

- Shoulder D-rings: This pair of D-rings, typically located on top of the wearer’s shoulders are utilized in conjunction with a yoke to facility confined space entry and/or rescue so that the user’s body remains upright so as to easily pass through a vertical hatch or man-hole.

- Waist/Rear D-ring: Typically located on a belt at or adjacent to the base of the wearer’s spine. This D-ring is intended only for use in restraint applications.

Next, let’s consider the basic harness styles. Full Body Harnesses are typically constructed in a few common styles in an effort to accommodate not only the D-ring configuration and functionality, but also to incorporate features that are preferred based on the needs of the end-user.

Vest-Style FBH’s are the most common and consist of vertical torso straps on the front of the wearer’s body, joined by a horizontal chest-strap, with a lower assembly consisting of a sub-pelvic strap and two leg straps. This type of FBH is donned, initially in the same manner as one would don a vest – hence the name. Based on the D-ring configurations available, these products are generally used for Fall Arrest, Work-Positioning, Restraint, basic ladder climbing and even confined space entry. This is generally the most basic style, and despite the simplicity, there are a wide variety of configurations available.

Construction-Style FBH’s are the next most common type, and are very similar to the Vest-Style, except that these FBH’s typically incorporate a work-belt with an integral waist pad to allow the wearer to also carry one or more tool bags. This waist pad/work-belt assembly also commonly incorporates a pair of hip D-rings for work positioning and have the added benefit of being more supportive for those who routinely engage in work-positioning activities for prolonged periods of time. Some of these FBH’s may also incorporate suspension slings and other supportive features to benefit those who are continuously expected to engage in hands-free work activity at height such as tower-climbers, wind-turbine technicians and derrick workers.

Cross-Over FBH’s are similar to the Vest-Style, except that the front torso straps cross one another above the wearer’s sternum and generally support a sternal D-ring (closely resembling the construction of the back D-ring location). These products are intended to for use in applications where the utilization of ladder climbing systems is common and/or highly frequent. These are generally regarded as a bit old-fashioned and uncomfortable and they are notoriously difficult to don and doff (put on and take off). However, it is absolutely the most secure and stable manner for creating the climbing attachment and they are much safer for that application than either a Vest or Construction-Style harness featuring a sternal D-ring.

The next series of distinguishing features will revolve around the specific materials utilized to construct the Full Body Harness. The webbing utilized in typical examples is polyester or nylon – both synthetic materials noted for high strength and tenacity and capable of dealing with the typical rigors in most applications.

In terms of the metallic components, steel is generally utilized due to its strength and the cost-effective nature of the material. Lower-price point harnesses will typically utilized stamped, low-carbon steel alloys, while higher-end products will use a combination of stamped and forged chro-moly steel due to the superior strength and resiliency of this more rugged alloy.

In applications where specific hazards or environmental conditions may be more aggressive, different materials may be utilized in an effort to mitigate these hazards and extend the life of the Full Body Harness. For example, aramid webbing such as Kevlar® or Nomex® may be utilized in situations where users are engaged in welding or may be exposed to electrical arc/flash hazards. PVC coated webbings are often used for users engaged in painting at height or in extremely dirty environments where the user is exposed to degrading contaminants such as mud, oil, grease or other substances are likely to cover and penetrate the user’s equipment and clothing.

Likewise, different alloys may be selected for the construction of metallic components to take advantage of their properties – stainless steel components may be utilized in highly corrosive environments, or in many cases, aluminum is utilized to reduce the overall weight of the product in an effort to make the user’s experience more comfortable.

With so many choices in terms of configuration, style and materials, it is important to carefully consider the needs of each group of users for whom you may be procuring product to ensure that their specific needs are being met. Almost without exception, each specific product is designed to address specific working conditions and application requirements, and rarely does one harness meet the needs of a large group of users.

While a lower price point and a more basic configuration may seem attractive, in many cases, it costs more in the long run to take a “one size fits all” approach to Full Body Harness selection. The most successful strategy is to carefully examine the needs of each working group and to ensure that the product that is selected provides them the flexibility they need to negotiate all of the hazards they are likely to encounter and to ensure that the selected product is appropriate not only for the application but for the environment in which they will be working as well.

What Are the Trigger-Heights for Fall Protection?

Title 29 of the Code of Federal Regulations outlines OSHA’s requirements for industry and application-specific thresholds triggering the mandatory use of fall protection.

At the most basic level, Federal regulations require that fall protection be provided at the following elevations above the next lower level:

- Four feet in general industry workplaces

- Five feet in shipyards

- Six feet in Construction

- Eight feet in long-shoring operations

- Ten feet for steel erection

- Thirty feet for decking operations.

Should I Use an Energy-Absorbing Lanyard or a Self-Retracting Lanyard?

The two most common Connecting Devices are Energy Absorbing Lanyards (EAL’s) and Self-Retracting Lanyards (SRL’s). As with Full Body Harnesses, choosing the correct connecting device is critical to the potential outcome, and requires careful consideration of all of the factors.

One of the most disturbing trends in Fall Protection today is the practice of issuing a blanket mandate that all workers on a job-site be equipped with a Personal SRL – mandates such as these do not take into account the advantages and disadvantages of specific connecting devices, nor do they fully consider the myriad fall hazards that may exist and the fact that each of these hazards may have unique characteristics that cannot be managed by a blanket mandate.

First, it is important to understand that both EAL’s and SRL’s are intended to function as connecting devices for fall arrest purposes and that each of these devices contains a mechanism for limiting the forces associated with fall arrest. With that said, it is of utmost importance to understand that these two types of devices have different capabilities and limitations and that they are absolutely not interchangeable.

EAL’s come in many configurations, and have their own very specific set of requirements, both within the context of OSHA Regulations and ANSI Standards. As with most fall arrest products, the ANSI Standards go beyond the OSHA regulations in terms of creating testing procedures and performance requirements, and at the most basic level and EAL is expected to:

- Have a minimum static strength of 5,000 lbs

- Must limit the arrest forces associated with either a six or a twelve foot free-fall.

- Must arrest a fall with a maximum deceleration distance of 48” – 60” (depending on free-fall distance)

- Must be subjected to environmental conditioning tests

- Must meet specific requirements related to dual-leg configurations, tie-back configurations, etc.

SRL’s also come in many different types and configurations. With that said, neither the OSHA regulations nor the ANSI standards have fully recognized many of these, and the requirements for these devices are not as stringent, nor are they as specific as the requirements for EAL’s. In fact, the basic assumption of both the regulations and the standard is that these devices are generally always mounted overhead so as to limit the free-fall distance to no more than two feet. The basic requirements for an SRL are as follows:

- Must have a minimum static strength of 3,000 lbs.

- Must limit the arrest forces associated with a free-fall of zero to two feet.

- Must arrest a fall in less than 54”

- Must be subjected to environmental conditioning tests

If you examine the basic requirements as outlined above, there are a few things that are a bit disconcerting. First and foremost, SRL’s are not expected to be as strong as lanyards – and generally speaking, they are going to be weaker by a factor of 20 – 40%. Furthermore, there is not standard or regulatory requirement for these devices to be put through testing with any significant free-fall imparted to the test mass, nor are application-specific variants required to go through any testing to evaluate whether they are fit for purpose.

In reality, SRL’s are generally superior to EAL’s if, and only if, they are tied off or mounted to an anchorage that is overhead and/or directly adjacent to the user’s back D-ring in a manner such that free-fall is limited to an absolute maximum of two feet. There may be a very few specific exceptions to this rule – but it will be necessary to engage in very specific conversation with your manufacturer of choice in order to make that determination. If you are to be subjected to a free-fall greater than two feet, in 99 out of 100 cases, you will be better off utilizing an application-appropriate EAL.

There are several FAQ’s in this series related to SRL’s – please take the time to read each of them, as you will find useful information that will provide a deeper understanding in terms of the advantages and disadvantages of these devices. An important take-away is this: SRL’s are among the most misused and misunderstood pieces of equipment in the fall protection arsenal.

This guidance may be contrary to what you have heard, or what you may have been told. If that is the case, ask some tough questions of your supply chain and ask for evidence of testing that demonstrates the superiority of EAL’s over SRL’s in circumstances that match the particulars of your application.What should I expect to pay for a Full Body Harness?

This depends largely on configuration, style, and quality. Full body harnesses featuring only a single back D-ring can be purchased for as little as $20 - $30. However, it is important to note that most of these are original equipment manufacturer (OEM) products, typically imported from China or India.

Products of this type are often manufactured to the very minimum requirements of their relevant ANSI standards. For example, the ANSI standard for full body harnesses (Z359.11), first published in 2015, reduced the minimum strength for harnesses. As a result, many of these products do not feature residual factors of safety that have long been expected in the North American Market.

Quality domestic products in the most basic configurations are generally available for as little as $60 - $70. More complicated configurations and styles may cost as much as $700.

In order to establish realistic expectations, a careful analysis of the application and hazards is required. The most cost-effective way of managing the expense associated with buying a FBH is to ensure that you have matched the harness to the craft. By doing so, you eliminate unnecessary features for those users who do not require them. For example, it’s smart to stick to single D-ring configurations for those not engaged in work-positioning. Matching the harness to the application provides advanced features only to those that need them.

Consult with a competent distributor to tailor an assortment that specifically meets the needs of your users.

What is the typical service-life of fall protection equipment?

This is entirely contingent on three specific factors:

- The environment in which the product is being used

- The behavior of the end-user

- The quality of the product

There are no standard or regulatory requirements dictating minimum or maximum life-span. This is a determination that will be made either during daily pre-use inspection or during periodic competent person inspections. Manufacturers are required to provide inspection guidance and criteria for all fall protection products.

Products used in aggressive environments or those subjected to the extremes of working conditions by way of the end-user’s behaviors will tend to wear out or become unserviceable more quickly. Those products that are utilized in less aggressive environments or by users whose activities are not as extreme will tend to last longer.

Almost any parent will recognize this dynamic. A docile child is more likely to outgrow their clothing than to wear it out. On the other hand, the more active and adventurous child will often wear their clothing out before they have an opportunity to outgrow it. The same is true with fall protection products, particularly those with textile components.

The quality factor will also play a part in the ultimate life-span of a product. Products with heavier-duty materials are most likely to last longer. This is especially true when those materials are selected on the basis of their resistance to the hazards and environmental conditions to which they will be subjected. A competent distributor can greatly assist with product selection to ensure you’re getting the most for your fall protection dollar. Beware of the deal that is too good to be true. Good is seldom cheap, and cheap is seldom good!

Can I continue to use my equipment if I fall while wearing it?

OSHA 1926.502(d)(19) states “Personal fall arrest systems and components subjected to impact loading shall be immediately removed from service and shall not be used again for employee protection until inspected and determined by a competent person to be undamaged and suitable for reuse.”

Standard practice in the industry is typically more stringent than OSHA’s guidelines - at least for harnesses and other textile-based equipment. If subjected to impact loading (the force generated by a fall), those components are generally removed from service immediately and destroyed to prevent re-use. Rendering harnesses unusable by cutting them into pieces is a standard recommendation from most, if not all, harness manufacturers.

Self-retracting lifelines (SRL’s) differ because they are mechanical in nature and not subjected to the same stresses as textile products. Most manufacturers recommend removing from service any SRL that has been subject to a fall. Devices are technically eligible to be returned to service if they pass inspection by a competent person. But this goes against most, if not all, manufacturer recommendations.

It has become more and more common for manufacturers to include a visual indicator that is built into the SRL that indicates whether or not the device has been subject to an impact load. Standard practice dictates that if a device has been used to decelerate a fall, it must be removed from service and returned to the manufacturer for recertification. Similarly, if there is visual indication that the device has been subject to an impact load, the device shouldn’t be reused.

If I fall, how will I get rescued?

OSHA 1926.502(d)(20) states “The employer shall provide for prompt rescue of employees in the event of a fall or shall assure that employees are able to rescue themselves.”

This standard addresses the hazard of being suspended by the fall arrest system after an arrested fall. Prompt rescue, as required under the standard, is not defined in the standard. While an employee may be safely suspended in a body harness for a longer period than from a body belt, the word “prompt” requires that rescue be performed quickly. It should be performed in time to prevent serious injury to the worker.

In short, the standard dictates that an employee’s rescue must be prompt, especially if the person is suspended by the fall arrest system. How that rescue occurs is essentially up to the employer. An in-depth analysis of the job site that takes into consideration potential risk factors associated with rescue is advisable. A written plan should be formulated and distributed to any potentially affected personnel. Simply relying on emergency services does not constitute an effective plan. This is especially true if high-angle rescue might be required, or if there are other structural or environmental factors in place that could affect standard rescue procedures.

What is a Suspension Trauma?

Suspension Trauma is a deadly condition brought on by an extended period of orthostatic intolerance. Orthostatic intolerance may be experienced by workers using fall arrest systems. Following a fall, a worker may remain suspended in a harness. The sustained immobility may lead to a state of unconsciousness. Depending on the length of time the suspended worker is unconscious/immobile and the level of venous pooling, the resulting orthostatic intolerance may lead to death. While not common, such fatalities often are referred to as “Harness Induced Pathology” or “Suspension Trauma”.

Orthostatic intolerance may be defined as “the development of symptoms such as lightheadedness, palpitations, tremulousness, poor concentration, fatigue, nausea, dizziness, headache, sweating, weakness and occasionally fainting during upright standing”. While in a sedentary position, blood can accumulate in the veins. This is commonly called “venous pooling,” and it can cause orthostatic intolerance. Orthostatic intolerance can also occur when an individual moves suddenly after being sedentary for a long time. For example, a person may experience orthostatic intolerance when they stand up quickly after sitting still for a long time.

Venous pooling typically occurs in the legs due to the force of gravity and a lack of movement. Some venous pooling occurs naturally when a person is standing. In the veins, blood is moved back to the heart through one-way valves using the normal muscular action associated with limb movement. If the legs are immobile, these “muscle pumps” do not operate effectively, and blood can accumulate. Since veins can expand, a large volume of blood may accumulate in the veins.

An accumulation of blood in the legs reduces the amount of blood in circulation. The body reacts to this reduction by speeding up the heart rate and in an attempt to maintain sufficient blood flow to the brain. If the blood supply is significantly reduced, this reaction will not be effective. The body will abruptly slow the heart rate, and blood pressure will diminish in the arteries. During severe venous pooling, the reduction in quantity and/or quality (oxygen content) of blood flowing to the brain causes fainting. This reduction can also have an effect on other vital organs, such as the kidneys. The kidneys are very sensitive to blood oxygen, and renal failure can occur with excessive venous pooling. If these conditions continue, they potentially may be fatal.

Unconscious or immobile workers suspended in their harness will not be able to move their legs. They will not fall into a horizontal position, as they would if they fainted while standing. During the static upright position, venous pooling is likely to occur and cause orthostatic intolerance, especially if the suspended worker is left in place for some time. Venous pooling and orthostatic intolerance can be exacerbated by other circumstances related to the fall. For example, shock, other injuries, the fit and positioning of the harness, environmental conditions, and the worker’s psychological state all may increase the onset and severity of the pooling and orthostatic intolerance. Unless the worker is rescued promptly using established safe procedures, venous pooling and orthostatic intolerance could result in serious or fatal injury, as the brain, kidneys, and other organs are deprived of oxygen.

Prolonged suspension from fall arrest systems can cause orthostatic intolerance. This, in turn, can result in serious physical injury, or potentially, death. Research indicates that suspension in a fall arrest device can result in unconsciousness, followed by death, in less than 30 minutes. To reduce the risk associated with prolonged suspension in fall arrest systems, employers should implement plans to prevent prolonged suspension in fall protection devices. The plan should include procedures for: preventing prolonged suspension, identifying orthostatic intolerance signs and symptoms, and performing rescue and treatment as quickly as possible.

OSHA recommends the following general practices/considerations:

- Rescue suspended workers as quickly as possible.

- Be aware that suspended workers are at risk of orthostatic intolerance and suspension trauma.

- Be aware of signs and symptoms of orthostatic intolerance.

- Be aware that orthostatic intolerance is potentially life threatening. Suspended workers with head injuries or who are unconscious are particularly at risk.

- Be aware of factors that can increase the risk of suspension trauma.

Rescue procedures should address the potential for orthostatic intolerance and suspension trauma. Rescue procedures also should address how the rescued worker will be handled to avoid any post-rescue injuries. They should include the following contingency based actions:

- If self-rescue is impossible, or if rescue cannot be performed promptly, the worker should be trained to “pump” his/her legs frequently to activate the muscles and reduce the risk of venous pooling. Footholds can be used to alleviate pressure, delay symptoms, and provide support for “muscle pumping.”

- Supplemental Safety Straps are available for retro-fitting onto most harnesses that, in the event of a fall, provide suspended workers with a means to relieve pressure and prevent venous pooling through use of a stirrup.

- Continuous monitoring of the suspended worker for signs and symptoms of orthostatic intolerance and suspension trauma is necessary.

- Ensure that a worker receives standard trauma resuscitation once rescued.

- If the worker is unconscious, keep the worker’s air passages open and obtain first aid.

- Monitor the worker after rescue, and ensure that the worker is evaluated by a healthcare professional. The worker should be hospitalized when appropriate. Possible delayed effects, such as kidney failure, which is not unusual in these cases, are difficult to assess on the scene.

What is a PFAS?

ANSI/ASSE Z359.0 defines a PFAS (Personal Fall Arrest System) as, “An assembly of components and subsystems used to arrest a person in a free fall”.

Typically, a PFAS consists of a full body harness, a connecting device, and an anchorage connector. At the most basic level, the full body harness contains/captures the body of the user. The anchorage connector affixes to the structure upon which the user is working. The connecting device both connects the user’s harness to the anchorage connector and manages the forces associated with the arrest. See “What are the ABCD’s of Fall Arrest” for additional details.

How much weight can my harness support?

By OSHA regulation and ANSI standard, 310 pounds is the maximum weight of the user, clothing, tools and equipment.

OSHA does recognize and allow an exception for a higher capacity, provided that “equivalent protection” is provided and validated by the manufacturer. The ANSI/ASSE Z359 Accredited Standards Committee has not yet recognized a product capacity higher than 310 pounds. The primary objection for increasing the capacity as it relates to the Z359 Fall Protection Code revolves around potential health risks. The objection refers to the risks associated with not only a fall arrest, but also the complications of orthostatic intolerance (Suspension Trauma) that may be experienced by a worker weighing more than 310 pounds.

In reality, many, if not most full body harnesses manufactured in the USA are capable of supporting the weight of users in excess of 400 pounds with no difficulty whatsoever. The determining factor in a successful fall arrest for a user of this weight will be the capabilities of the EAL or SRL which is utilized to arrest the fall. In theory, a typical FBH manufactured “large” enough would support the weight of a full-size passenger car.

However, the deceleration device dictates the condition of the harness following a dynamic fall arrest. If it’s capable of limiting maximum arrest forces to less than 1,800 lbs. and prevents the user from hitting the next lower level or an object in the fall path, then the harness will survive the event. The most important factor is ensuring the end-user is promptly rescued and receives immediate medical attention. It should be made clear that they have not suffered any internal injuries and are not demonstrating any symptoms of orthostatic intolerance.

For users requiring a PFAS rated for greater than 310 pounds, please consult your manufacturer of choice. You may also consult with a competent distributor to assist with product selection and fall protection planning.

How can I tell if my harness fits properly?

Proper fit will only occur if the harness has been donned properly. Review the manufacturer instructions included with your harness for details pertaining to donning your particular harness, as there may be accessories or harness-specific factors that will affect proper donning and fit.

For a standard full body harness, the following instructions for donning and adjustment can be used:

- Grasp your harness by the back D-ring and back plaque. Be certain the straps are not twisted, and thoroughly inspect for damage.

- Place the harness over your arms and onto your shoulders. The shoulder straps should remain vertical on your chest.

- Grasp the leg straps and connect to the buckles attached to the straps on each hip. Insert the excess strap through the keepers (if equipped). Leg straps should be snug.

- Attach the chest strap by passing the male buckle through the female buckle. The strap should be at your upper chest level. Retain the excess strap with its keeper (if equipped).

- To tighten the shoulders, pull up on the free ends of the straps. To loosen, push down on the adjuster and adjust the straps. The straps should be adjusted to the same length. Stand up straight and adjust the length of the shoulder straps as needed to make sure there is no slack.

- The back D-ring should be centered between your shoulder blades. To adjust, slide the D-ring and plaque up or down along the webbing.

A properly fitted harness should be snug, but not tight enough to prevent normal movement. With your hand held flat, you should be able to fit your fingers underneath your leg straps. Always properly adjust your harness before use, as proper fit will ensure proper function.

What’s the difference between tongue-buckles and pass-thru closures?

Tongue-buckle and grommet fasteners, as well as pass-thru buckles are the most common forms of fasteners found on modern full body harnesses.

Tongue-buckle fasteners incorporate a traditional belt-buckle style closure. They have a prong that fits into a metal grommet which has been inserted into the fabric of the harness. While a reliable method of closure, it has the drawback of being binary in terms of sizing. There is no room for adjustment between the grommets. However, harness sizing adjustment is typically easier, especially when wearing gloves.

Pass-thru buckles (also commonly referred to as ‘parachute buckles’) feature a male/female closure system. The male end passes through the opening in the female buckle creating closure between the two ends. Placement of the web through the buckle typically provides for a higher degree of custom adjustment than grommet and tongue-buckle fasteners. Also, use of pass-thru buckles tends to reduce the overall weight of the harness depending upon the materials used. Pass-thru buckles are standard chest strap fasteners on the majority of harnesses.

The term ‘parachute buckle’ is also often used to describe more contemporary fasteners, which utilize a male component that is inserted into a female component. The female component incorporates a mechanical latching system to hold the male component in place.

What are the ‘ABCD’s’ of fall protection?

The ABCD’s of Fall Protection are used to describe the components of a personal fall arrest system (PFAS), restraint system or work-positioning system.

A is for Anchorage: Keep in mind that anchorage is really discussing two different components. An anchorage is the structural element to create an attachment or “tie-off” point on the structure that the user is working upon or adjacent to. An anchorage connector is the device affixed to the structural anchorage in order to establish a compatible connection.

B is for Body Support: In today’s language, this means a full body harness (FBH). It’s legal to utilize a body belt or a “seat harness” for work-positioning or restraint. But they are by no means recommended. Any reputable employer should provide full body harnesses to workers exposed to falls from height, regardless of application. A FBH will capture and retain the worker in the event of a fall. When properly designed and utilized, it will distribute arrest forces to the more robust parts of the worker’s body to help reduce the risk of injury.

C is for Connecting Device: The connecting device is the element that attaches the user’s FBH to the anchorage connector to facilitate fall arrest, restraint, or work-positioning. This is most typically a lanyard of some description, a self-retracting device, or a vertical lifeline.

D is for Deceleration Device: This is the component that limits the forces transmitted to the user’s body and/or the anchorage in the event of a fall arrest. It may take the form of an extensible energy absorber, or it may be the rotary brake element of a self-retracting device. In any case, the deceleration device is an integral part of the connecting device used for fall arrest purposes.

How does an energy absorbing lanyard work?

Energy absorbing lanyards, as you might expect, feature an energy absorber that is designed to limit the forces associated with fall arrest. Both OSHA regulations and ANSI standards dictate that the maximum force that can be imparted to a human person (or to the anchorage) is 1,800 lbs. (8 kN).

The two most common methods for constructing a personal energy absorber is through the use of a “tear-tape” or a POY webbing (partially oriented yarn, or pre-oriented yarn).

A tear-tape is a length of webbing (usually polyester or nylon) which consists of two distinct layers that are bound together along most of its length by “binder yarns”. The tear-tape is stitched into an energy absorber assembly in such a way that there are two opposing ends, each of which joined to one of these distinct layers. At the end of the free-fall phase of the fall arrest cycle, the two opposing ends of the energy absorber assembly are pulled apart when the lanyard leg becomes taut. The “binder yarns” begin to yield and the two layers are torn apart at a controlled rate. This is essentially like stepping on the brake pedal in your car. As the two layers are torn apart, the falling mass is brought to a stop much more gently than if no energy absorber were involved. A well-constructed energy absorber assembly will include a back-up strap to prevent the two layers of tear-tape from being torn apart in the event of a dynamic overload.

A POY energy absorber (sometimes called an internal or integral energy absorber) works a bit differently. The energy-absorbing material runs the entire length of the lanyard. It’s constructed from pre-oriented yarns (the most raw form of synthetic yarn) woven together in loose bundles in a contracted state. This POY material is stuffed into a tubular webbing (typically polyester or nylon) which is longer than the POY core by a factor of four to five feet. The excessive tubular webbing is gathered to one end and tack-stitched in place. It may also be allowed to float the length of the core, and it may integrate an elastic band to allow the lanyard to expand and contract along its length. These are sometimes referred to as bungee style lanyards.

In either case, as the lanyard becomes taut at the end of the free-fall phase of the fall arrest, the contracted bundles of the POY material expands along its entire length. This dissipates the forces associated with the fall arrest. The outer, tubular webbing functions not only as a protective jacket for the POY material. It also serves as the back-up strap, or load bearing element, of this type of energy absorber.

The POY style EAL’s are economical to manufacture and are excellent in “straight up and down” fall arrest scenarios. They are, however, limited in their effectiveness. This is because the entire lanyard leg must be unencumbered in order for the energy absorber to deploy fully and without restriction. These types of EAL’s should never be used when any type of edge contact may be made. These scenarios may include aerial lifts, working adjacent to a guardrail, or in any leading-edge or wrap-around (tie-back) type of application. The isolation of any segment/length of the energy-absorbing core may overload the active length, causing it to break.

Tear-tape style energy absorbers are the most versatile and most appropriate for a wide range of applications. They’re also beneficial for use with specialty lanyards. Additionally, the isolation of the tear-tape energy absorber assembly in traditional shock-pack configurations protects the assembly from incidental damage during the course of work. This ensures that the assembly will be there for you when you need it.

For either of these products, the energy absorber elements are typically qualified to meet both OSHA regulations and ANSI standards. They’re designed so that maximum arrest forces do not exceed 1,800 pounds, and so that the deceleration distance of the energy absorber does not exceed the prescribed limits depending on type. This distance will range from 42 to 60 inches, depending on whether the product is qualified according to Subpart M, Appendix C, or the 6FF or 12FF requirements of ANSI/ASSE Z359.13.

How does an SRL work?

This is a question that very few people can answer definitively and accurately. There are a lot of misconceptions about SRL’s. Some of these have been exacerbated by new developments in the manufacturing sector and by newer requirements in the ANSI Z359 standards over the last five years.

Let’s begin by discussing what a traditional SRL is. Self-retracting lifelines are devices that contain a reel with an integral line tied to a heavy-duty clock spring. These devices have traditionally been mounted to overhead anchorages above the walking-work surface. When tied-off to an SRL of this description, the worker will have the ability to access a reasonably-sized working area. They have the additional ability to ascend or descend, with the SRL line either paying out or automatically retracting to eliminate slack. In the event of a fall, the reel will lock and begin the fall arrest sequence.

This was the landscape for SRL’s for many decades. In the early 2000’s, the first “compact” or “personal” SRL’s were introduced. These units were miniaturized and were offered as an alternative to energy-absorbing lanyards (EAL’s). Many manufacturers began prescribing them for “wear” on the back D-ring of a full body harness in lieu of the traditional EAL. Some of these were described as “fall limiters.” Many manufacturers claimed that they were superior to EAL’s because they reduced the tripping hazards associated with a fixed length lanyard hanging off of a user’s harness. They could also arrest a fall in a shorter distance since they didn’t require a free-fall distance equivalent to the length of the traditional 6 foot EAL.

The problem with this philosophy is that there were no testing requirements that created an accurate comparison of the capabilities of these “fall limiters” vs. the traditional EAL’s. As these early models were introduced, it wasn’t anticipated that they would be used to make connections to anchorages that were not always going to be overhead. As a result, these units were subjected to free-fall distances that weren’t anticipated by the testing protocols established in the OSHA regulations and the ANSI standards. The result has been a mixed bag of performance results. Many users have employed these devices in a potentially dangerous manner.

Additionally, the ANSI Z359.14 standard for SRL’s was published in 2012. This document took the original requirements of the earlier Z359.1 standard and expanded upon them. As a result of the introduction of personal SRL’s and the Z359.14 standard, we now have different types and classifications of products. Not everyone has a clear picture of what these types and classes are, what they are capable of, and what the appropriate uses and limitations are. Let’s examine these, and then we will break down how they work.

First, based on the language of Z359.14, we have three types of devices. A fourth type is being defined and is currently in the process of being drafted for a new edition. Each type is lumped together under the new name “self-retracting devices” (SRD’s) which are defined as:

“A device that contains a drum-wound line that automatically locks at the onset of a fall to arrest the user, but that pays out from and automatically retracts onto the drum during normal movement of the person to whom the line is attached. After the onset of a fall, the device automatically locks the drum and arrests the fall. Self-Retracting Devices include Self-Retracting Lanyards (SRL’s), Self-Retracting Lanyards with integral rescue capability (SRL-R’s) and Self-Retracting Lanyards with leading edge capability, and hybrid combinations of these.”

Let’s briefly examine each of these, as well as the SRL’s of the personal type:

SRL’s: Self-retracting lanyards are intended to be mounted to a fixed anchorage, horizontal lifeline, or rail system or trolley. They’re generally mounted overhead, and they can be rigged to limit free-fall to a maximum of two feet. These devices provide a degree of lateral and vertical movement for the user.

SRL-R’s: This type consists of a self-retracting lanyard with an integral rescue capability. This capability uses an integral retrieval winch, which will allow a fallen or injured worker to be raised or lowered. These devices are most commonly used in confined space applications. They may be used interchangeably with SRL’s, provided that the rescuer has access to the rescue mechanism.

SRL-LE: Self-retracting lanyards for leading edge exposures are required to have a supplemental energy absorber at the point of attachment to the user’s FBH back D-ring. These units are designed to protect steel erectors who may be exposed to leading edge falls. They often feature a larger diameter wire rope constituent line to resist cutting and abrasion. These devices should be used as a last resort, as the application has a high degree of risk. Also, the qualification testing required by the ANSI Z359.14 standard is not comprehensive. It doesn’t anticipate hazards that may be damaging to the SRL line, such as unbeveled concrete, metal decking and joints, or gaps between beams and columns.

SRL-P: Personal or “compact” SRL’s are designed to be worn and utilized in lieu of energy-absorbing lanyards. These devices are ideal for attaching to anchorages that are overhead or directly adjacent to the back D-ring of the user’s full body harness. Not all units are tested in extremes of free-fall. The increased dynamic loads resulting from reduced anchorage height can produce forces that may exceed the capacity of the energy-absorbing element of the device. This may damage the structural integrity of the device if the energy-absorbing element is overloaded.

Having described and defined the basic types, there are also two classes that are specified in the ANSI Z359.14 standard that apply to the SRL, SRL-R and the SRL-P:

- Class A devices, when subjected to dynamic performance testing, should have an arrest distance not exceeding 24 inches, a maximum arrest force of 1,800 pounds, and an average arrest force of 1,350 pounds.

- Class B devices, when subjected to dynamic performance testing, should have an arrest distance not exceeding 54 inches, a maximum arrest force of 1,800 pounds, and an average arrest force of 900 pounds.

Note: These performance thresholds only hold true in actual practice if the SRD’s are mounted overhead. In the event of a free-fall, the performance characteristics will change, particularly with respect to the SRL-P or Personal Device.

Now, we can discuss the functional elements that make an SRD work. There are two principle elements that are critical to fall arrest: the locking mechanism and the energy-absorbing element.

There are three ways to create a locking engagement of the drum in a SRD:

Centrifugal locking mechanisms are the most common. These consist of one or more pawls, or an articulating lever or claw. They’re activated by the centrifugal motion of the drum as the line is extracted during the course of the fall. As the pawl swings outwardly, it engages the teeth of a gear, ratchet ring, or sperrad in order to create the locking engagement. The downside of this type of mechanism is that it can be susceptible to fouling. This caused by corrosion or invasive contaminants, including dirt, grease, or oil. If fouling occurs, the mechanism may fail to engage.

Inertial Locking Mechanisms are similar to the seat-belt assemblies in automobiles and function on the basis of acceleration. The acceleration of the spinning drum after the initiation of a fall spins an internal shaft. It puts pressure on a lever assembly that will force a locking engagement to take place. These mechanisms aren’t popular as they’re overly complicated. They also don’t work well in sliding falls or engulfment scenarios, such as in grain silos.

Mechanically-Activated Locking Mechanisms are similar to centrifugal locking mechanisms in that they will also feature locking pawls (generally two or more). In this case, however, the pawls are not entirely dependent on centrifugal force. Instead, they’re driven into engagement by a rotating cam. The advantage of this type of mechanism is that it is not susceptible to failures caused by corrosion or invasive contamination. They are typically more expensive to manufacture, but are the most reliable.

Once the locking engagement has taken place, the SRD needs to dissipate the forces associated with a fall arrest to protect both the worker and the integrity of the anchorage. This is where the energy-absorbing element comes into play.

There are three basic methods used in SRD’s to absorb energy:

Rotary Brake Method: This is the traditional method, particularly for versions utilizing wire rope as the constituent line. The rotary brake is an assembly consisting of a pressure plate and an abrasive brake disc. The disc is located on one side of the drum, and is held in place by a nut and belleville washer on the axis of the main-shaft or axle. When the locking engagement takes place, the drum is allowed to continue spinning under the pressure of the brake, bringing the falling mass of the user to a stop. This is the most efficient and effective method of absorbing energy, as this brake assembly can generally be tuned to achieve desirable results. Additionally, if the unit has a reserve line (excess line that can’t be pulled out of the unit under normal circumstances) the energy capacity can be virtually unlimited, dependent on the length of the reserve line.

Compression-Elastic Method: This is also a traditional method, but it’s only relied upon in units that use polyester or nylon webbing for the constituent line. In this method, the natural elasticity of the webbing itself, and the tightening or cinching of the webbing around the drum following the locking engagement, is sufficient to absorb the energy associated for a fall. This is provided that the unit is mounted overhead. The downside of this method is that if the unit is not mounted overhead, any significant free-fall can result in a serious force-spike. The force-spike can result in an MAF greater than 1,800 pounds, or in some cases, greater than 3,000 pounds. Additionally, if the webbing is significantly worn or degraded, its ability to manage forces may be considerably diminished.

Tear-Tape Energy Absorber: In the case of some smaller devices, particularly SRL-P’s, a tear-tape energy absorber is utilized. This is not unlike the type you would typically see on an energy absorbing lanyard. More often than not, this element will be located adjacent to the anchorage-end connector. Once the device has locked up, the tear-tape takes over and expands as it would on a lanyard. This brings the falling user to a stop with a maximum arrest force of less than 1,800 pounds. This method is effective. However, in some cases, a shorter length of tear-tape is used - as very little is required to pass the ANSI Z359.14 testing. If any significant free-fall may occur, then additional energy absorber capacity may be required.

As we have illustrated here, how SRL’s work is a somewhat loaded question. There are a lot of issues to consider, and these devices are not necessarily as straight-forward as they may seem. It is important to work closely with your manufacturer of choice or with a competent distributor to make sure that you are selecting a product that is appropriate for your application. Self-retracting devices are a great solution, but they are not always the best choice. Do your homework before making decisions about how these devices are to be employed by your organization.

What is ‘Swing Fall’?

The ANSI/ASSE Z359.0-2012 standard says, “swing fall is a pendulum-like motion that occurs during and/or after a vertical fall. A swing fall results when an authorized person begins a fall from a position that is located horizontally away from a fixed anchorage.”

Swing falls are typically associated with the use of a self-retracting lifeline, primarily because an SRL can be installed at a height greater than that of a shock absorbing lanyard. If cable is paid out of the device as a result of the user moving away from the device horizontally, a fall (and the subsequent locking of the SRL) will cause the user to ‘swing’ like a pendulum back towards center.

Can I tie off at my feet (ground level)?

It is always a best practice to avoid this if possible. The difficulty with this practice is that it requires a great deal of clearance between the walking-working surface and the next lower level. Furthermore, any objects or equipment in the fall path present a significant hazard as well. In many cases, the available clearance is not uniform across broad areas.

There are energy absorbing lanyard and self-retracting devices of various makes and models that are designed for these circumstances. Depending on the type of product and the capabilities of your preferred brand, the clearance required between levels to safely arrest a fall will be anywhere between 13 and 18 feet. If we consider steel erection as a benchmark, typical clearances between levels range from 10 to 15 feet. That leaves little margin for error. If we consider working within pipe-rack, those clearances can be considerably less.

The best outcomes will always come from utilizing overhead anchorages. If there is no suitable overhead structure to tie into, horizontal lifelines or portable ballasted devices may be options worth exploring. If such measures aren’t feasible, OSHA does allow free-falls up to twelve feet. However, this is provided that equivalent thresholds of protection are provided to those workers (maximum arrest forces not to exceed 1,800 lbs.), and provided that they do not strike a lower level or an object in the fall path.

What is the difference between a positioning lanyard and an Energy Absorbing Lanyard (Shock Absorbing Lanyard)?

Positioning Devices: In the simplest of terms, a positioning lanyard is designed to be used as part of a system (with a full body harness and anchorage). The system prevents the user from being exposed to a fall hazard by limiting range of movement towards a hazardous area where a fall might occur. Positioning systems are also commonly used to allow users to work hands-free.

ANSI Z359.0-2012 provides the following definitions:

Positioning: The act of supporting the body with a positioning system for the purpose of working with hands free.

Positioning Lanyard: A lanyard used to transfer forces from a body support to an anchorage or anchorage connector in a positioning system.

The standard states that positioning lanyards may be fixed length or adjustable, and are part of a positioning system. Although positioning systems may use the same equipment as a fall protection system (such as a harness), a positioning system used alone does not constitute fall protection. While positioning, a person is exposed to fall hazards. Therefore, they’re required under these standards to use a separate system that provides backup protection from a fall.

For example, a user who is utilizing a positioning system so that he can tie rebar must also use a fall protection element (energy absorber, SRL, etc.) to prevent a potential fall.

Energy Absorbing Lanyards: These are also referred to as “energy absorbers” or “shock absorbers.” ANSI defines them as “a component whose primary function is to dissipate energy and limit deceleration forces which the system imposes on the body during fall arrest. Such devices may employ various principles such as deformation, friction, tearing of materials, or breaking of stitches to accomplish energy absorption. An energy absorber causes an increase in the deceleration distance. An energy absorber may be borne by the user (personal) or be a part of a horizontal lifeline subsystem or a vertical lifeline subsystem.”

In terms of usage, an energy absorbing lanyard is appropriate for use over a positioning lanyard if the potential for a fall exists. If the use of a positioning lanyard can prevent the user from being exposed to a fall hazard, it is more appropriate for use.

How can I tell if my anchor location is strong enough to support my system?

There are two basic sets of guidance for anchorage strength. The OSHA regulations stipulate that a fall arrest anchorage must support a static weight of 5,000 pounds per user attached, or that a system must be designed to provide a safety factor of two.

The 5,000 pound rule is pretty simple. That number was originally derived in an effort to help users visualize the strength of the anchor. If you can’t imagine a full-sized automobile suspended from the anchorage you intend to tie-off to, then you may need to rethink your anchorage.

The 2:1 rule is the basis for a great deal of fall protection design logic. The objective here is to ensure that any design is developed with consideration of the anticipated loads, and that the minimum strength target was sufficient to provide a margin for error.

ANSI/ASSE Z359.2 and Z359.6 are exceptional resources for fall protection planning and design, and are useful end-user references. The best practice is to involve a qualified person or professional engineer in the selection and designation of anchorages. This will ensure that the strength requirements are being met.

What are the OSHA & ANSI standards that apply to fall protection?

The OSHA standards pertaining to general industry are OSHA 1910, Subpart D, Walking and Working Surfaces. This includes (but is not limited to) requirements for fixed ladders, ladder safety devices, and safety requirements for scaffolding and boatswain’s chairs:

- Proposed Subpart I, Personal Fall Arrest Systems

- 1910.66 Subpart F, Powered Platforms and Building Maintenance

- 1910.146 Subpart J, Permit - Required Confined Space

OSHA 1910, Subpart R, Special Industries includes:

- 1910.268 Telecommunications

- 1910.269 Electric Power Generation, Transmission and Distribution

The OSHA Standards pertaining to Construction are:

- OSHA 1926, Subpart E, Personal Protective Equipment

- 1926.104 Safety Belts, Lifelines and Lanyards

- 1926.105 Safety Nets

Subpart L, Scaffolding:

- 1926.451 (g) (1) Boatswain’s Chair

Subpart M, Fall Protection:

- 1926.500 Scope, Application and Definitions

- 1926.501 Duty to Have Fall Protection

- 1926.502 Fall Protection Systems Criteria and Practices

- 1926.503 Training Requirements

Subpart R, Steel Erection:

- 1926.760 Fall Protection

The ANSI standards relating to Fall Protection are as follows:

- A10.14-1991 Construction and Demolition Operations: Requirements for Belts, Harnesses, Lanyards and Lifelines

- A14.3-1992 Ladders, Fixed, Safety Requirements

- Z117.1-1989 Safety Requirements for Confined Spaces

- Z359.1-1992 Safety Requirements for Personal Fall Arrest Systems, Subsystems and Components

What are the penalties for being cited for fall protection violations?

What is the OSHA standard that applies to entry and retrieval for permit-required confined space?

The applicable standard is OSHA 1910.146 Subpart J, Permit-Required Confined Spaces: (a) Scope and Application. This section contains requirements for practices and procedures to protect employees in general industry from the hazards of entry into permit-required confined spaces.

Section (k)(3) discusses non-entry rescue. It mandates that to facilitate non-entry rescue, retrieval systems or methods shall be used whenever an authorized entrant enters a permit space. This is necessary unless the retrieval equipment would increase the overall risk of entry or would not contribute to the rescue of the entrant.

Retrieval systems shall meet the following requirements:

- Each authorized entrant shall use a chest or full body harness, with a retrieval line attached at the center of the entrant’s back near shoulder level. It can also be attached above the entrant’s head or at another point which the employer can establish presents a profile small enough for the successful removal of the entrant. Wristlets may be used in lieu of the chest or full body harness if the employer can demonstrate that the use of a chest or full body harness is infeasible or creates a greater hazard. They must also demonstrate that the use of wristlets is the safest and most effective alternative.

- The other end of the retrieval line shall be attached to a mechanical device or fixed point outside of the permit space so that rescue can begin as soon as the rescuer becomes aware that it’s is necessary. A mechanical device shall be available to retrieve personnel from vertical type permit spaces more than 5 feet deep.

What’s the difference between a screw-lock and a self-locking carabiner?

ANSI Z359 defines a carabiner as “a connector generally comprised of a trapezoidal or oval shaped body with a closed gate or similar arrangement that may be opened to attach another object and, when released, automatically closes to retain the object.” Note that “carabiner” may also be spelled “karabiner.”

There are generally three types of carabiners:

- The automatic or self-locking type (required by these standards) with a self-closing, self- locking gate that remains closed and locked until intentionally unlocked and opened for connection or disconnection

- The manual locking type (not permitted by these standards) with a self-closing gate that must be manually locked by the user and that remains closed and locked until intentionally unlocked and opened by the user for connection or disconnection

- The non-locking type (not permitted by these standards) with a self-closing gate that cannot be locked

A screw-lock carabiner falls under the second description, as the “screw” aspect requires a separate action to lock the carabiner gate in the closed position. A self-locking carabiner falls under the first description, as these types require separate actions to unlock and open the gate. Both actions are automatically performed to close the gate upon release.

What’s a double-locking snap hook?

ANSI Z359 defines a snaphook as “a connector comprised of a hook-shaped body with a normally closed gate or similar arrangement that may be opened to permit the hook to receive an object and, when released, automatically closes to retain the object.”

Snaphooks are generally one of two types:

- Automatic-locking type (required by these standards) with a self-closing and self-locking gate which remains closed and locked until intentionally unlocked and opened for connection or disconnection

- Non-locking type (not permitted by these standards) with a self-closing gate which remains closed, but not locked, until intentionally opened for connection or disconnection

The term “double-locking snaphook” is defined by the “automatic locking type” definition given above. The “double” refers to the separate actions required to unlock and subsequently open the gate. It also refers to the self-closing and self-locking operations that take place once the hook is released.

What is a Pelican hook?

In fall protection terminology, a “Pelican” hook is usually meant to reference a hook with a large gate opening, typically in the 60mm (2 - 2-1/4”) range. These types of hooks are often referred to as “rebar” hooks due to their association and common incorporation into rebar chain assemblies, which are used for work positioning when tying rebar. The term “Pelican™” also applies to 19mm (3/4”) opening snaphooks designed and manufactured by Reliance Fall Protection. The name is reflective of the shape of the hook and it's resemblance to the beak of a pelican.

How can I tell what HLL system is right for me?

The simple answer is that you may not be able to make that determination based simply upon examining existing, pre-packaged options. Designing and installing a horizontal lifeline system that provides effective fall protection is based on a number of factors. Some factors may require consultation from experts in the field.

In typical lifeline systems, the actual lifeline (the span of cable that constitutes the length of the system) does not vary much from system to system. That aspect of the system typically consists of:

- The span of cable

- An energy absorbing element

- Connecting elements (to the anchor points)

- Intermediate supports (the type and number determined by the length and location of the entire assembly)

The largest variety in systems construction is the type of anchorage devices used to anchor the endpoints of the system. Those anchorage devices are typically designed to be used in specific environments where consistent, functionally appropriate anchor points can be found.

Specific anchorage points are available for structural steel assemblies, road and bridge environments, and concrete construction. Each of these have structures that can accommodate HLL anchors built for use in those places. Custom anchor points are often also a possibility. If you are uncertain about which system will best accommodate your needs, don't hesitate to ask and expert.

What is a ‘Y’ (or double-leg) lanyard?

A “Y” lanyard may also be called a 100% tie-off, double-leg, or twin leg lanyard. It’s an energy absorbing lanyard that consists of two separate lanyard legs. It has two separate energy absorbers and end point connectors, but only one harness connecting element (typically a hook or a web loop).

From a functional standpoint, they work in precisely the same manner as a single-leg lanyard. If a fall occurs, they decelerate the user and absorb the energy generated by the fall. The incorporation of the second leg is designed to offer the user a way to traverse distances where multiple anchor points are available, but the distance to traverse exceeds the length of a single lanyard leg.

In these cases, where the user must remain tied off 100% of the time, the user can attach to an anchor point with the first leg. This allows them to traverse the distance allowed by the lanyard, attach the second lanyard to the next suitable anchor point, detach the first lanyard, and proceed. Multiple scenarios exist where Y-lanyards can be used, dependent upon the nature of the user’s movement within the work space.

What is a tie-back lanyard?

A “tie-back” lanyard is an energy absorbing lanyard. It allows the user to wrap the lanyard itself around a suitable anchorage point, and then attach the lanyard snaphook to the webbing of the lanyard leg. OSHA states that, “Unless a snap hook is a locking type specifically designed for the purpose of tying back into a lanyard, it shall not be engaged directly to webbing, rope, or wire rope.”

In the event of a fall, the process of “tying back” a lanyard into itself could expose the snap hook gate to forces that exceed the design specifications and those outlined by ANSI 359.1. In standard (non tie-back) hooks designed for use with fall protection devices, the gate is the weakest link of the hook. When forces engage upon the front or side of snap hook gate, the hook can break or deform. This created the necessity for a hook specifically designed not to fail under those circumstances. Under no circumstances should a user ever tie a lanyard back into itself unless that lanyard is specifically designed for that purpose.

What’s the difference between a Self-Retracting Lanyard and a Self-Retracting Lifeline?

These are two terms are often used interchangeably in the Fall Protection business. In reality, self-retracting lanyard is the preferred term, based on the types and classes of self-retracting devices that were further defined in the ANSI/ASSE Z359.14 standard back in 2012.

How can I tell if an SRL has been subject to a fall?

Since 2012, it has been a requirement of the ANSI/ASSE Z359.14 standard that all self-retracting devices must include a “visual indicator” that will create visible evidence the device has been subjected to a fall.

In many cases, this is a simple roll-pin or shear-pin that is part of the snap hook assembly. In the event of a fall, the pin shears off, revealing an identifying collar or mark.

For devices featuring a webbing constituent line, the visual indicator may be a simple label or flag. It’s stitched to the webbing near the hook of the nozzle at the bottom of the housing, which is concealed in a section of the webbing that has been folded and stitched down. The force of the arrest breaks the stitch and reveals the concealed label.

Check the manufacturer’s instructions for your preferred device for specific details on the visual indicator and how to determine the go/no-go criteria for your device.

How often do SRL’s need to be re-certified by the factory?

This is dependent on the manufacturer. There are some manufacturers that do not require recertification or periodic factory authorized service. Those manufacturers that do typically go with a period of every one to two years.

The ANSI/ASSE Z359.14 standard published in 2012 included a specific schedule as a normative part of the standard. In 2014, the schedule was revised to be optional due to complaints registered by a small number of manufacturers and end-users.

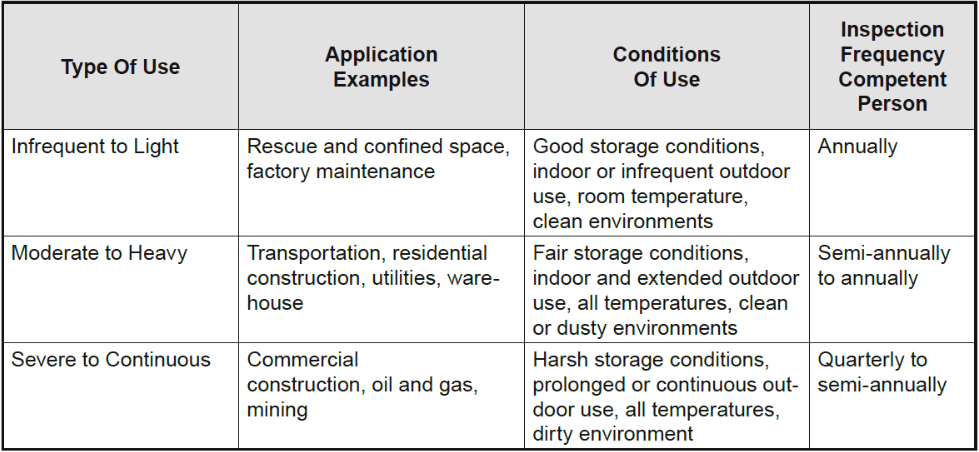

The current, recommended guidance from the Z359.14 standard is as follows:

Keep in mind that the environment that the device is used in, and the behaviors of the users themselves will ultimately dictate the frequency of recertification. Be sure to follow the guidance for pre-use.

Is an SRL with a steel case better than one with a polycarbonate case?

Not necessarily. There are several factors that may make one SRL better than another. If you want to get the best SRL, look for these things:

Mechanically Activated Locking Mechanism: This type of locking mechanism is the least likely to be susceptible to failure resulting from corrosion or invasive contamination. Contamination can occur due to dirt, oil, grease, paint or any other substance drawn into the device by the constituent line as it pays-out and retracts.

Energy Capacity or Free-Fall Rating: The capability of the device to deal with severe dynamic loads while limiting forces is critical. Many manufacturers simply “test to the standard,” which does not require imparting free-fall to the test mass in an effort to quantitatively determine how the device performs. This is particularly crucial when we are looking at personal SRL’ s. Seek out devices that have been tested beyond the scope of the ANSI Z359.14 standard.

Ultimate Strength: Would it disturb you to know that SRL’ s are the only product class that is not required to provide at least a 2:1 safety factor in static testing under the ANSI Z359 standards? The minimum strength requirement is only 3,000 lbs., while the maximum arrest force is allowed to be as high as 1,800 lbs. Many SRL’ s are capable of sustaining a higher static load. Seek these units out, as the residual factor of safety is higher.

In terms of construction, many plastic cases are merely “shells,” and the SRL may feature an aluminum or steel frame. The shell, in this case, is not load-bearing, but merely exists to protect the internal components from the elements.

In some cases, the plastic housing may be semi-structural. This means that it is reinforced with steel or aluminum elements which are designed to carry the fall arrest loads. Generally speaking, devices with metallic frames and/or reinforcements are going to be just as capable as those with metallic housings.

In some plastic units, the plastic housing is load-bearing. While these may meet the requirements of the ANSI/ASSE Z359.14 standard in new condition, it is important to note that a damaged case may be a significant hazard.

Engineered plastics have come a long way. However, it’s important that you “pop the hood” on an SRL before you make a purchasing decision so that you know what you are getting. The material of the housing is not as important as what the housing may be concealing from your view prior to making a buying decision.

What’s the difference between a compact SRL and a full size SRL?

There are several differences, but the most noticeable difference is simply the size, or the working length. Most compact or personal SRL’ s are offered in working-lengths of 6 feet, up to a maximum of 10 or 12 feet. Anything longer than that starts to become a little unwieldy. Since these devices are generally used interchangeably with energy-absorbing lanyards, there is an expectation that they be small and reasonably lightweight.

Another difference is that the constituent line in a personal SRL is typically going to be webbing. Larger, full-size SRL’ s are going to use wire rope. The reason for this is also to control the size and the weight. Wire rope weighs more than webbing, and also requires a wider drum diameter in order to be effectively wound.

Finally, most full-size SRL’ s utilize an internal rotary brake to manage energy absorption. Due to the constraints on the size and weight of the personal devices, this is typically not practical. External tear-tape energy absorbers are generally used on smaller devices.

Should a compact SRL be worn on my back or should I connect to it like a full size SRL?

This depends entirely on the application. It is pretty rare to see personal SRL’ s mounted to overhead anchorages in the manner of a larger traditional unit. A common exception is when these devices are mounted to order-picking lift-trucks. Since the walking-working surface is so small and since there is an integrated anchorage overhead, this is a practical solution in that application. Outside of this scenario, it is a pretty rare practice.

In any event, always be sure to mount and/or wear these devices in accordance with the manufacturer's instructions. Your manufacturer of choice and your competent and qualified persons will always be your best resource for guidance on what is appropriate for your equipment.

When would a Twin-Leg compact SRL be the best option?

This would be the best option in a scenario where your anchorages are routinely located at or above the level of the back D-ring of a user's FBH. In these situations, the arrest distances will be limited and your clearance requirements will be reduced. If you do not have these types of anchorage elevations, you need to reevaluate your desire to use personal SRL’ s. Many may not perform as well as you think. You may find yourself with inadequate clearance, or with a device that may not be capable of dealing with the force inputs that will result from a fall arrest.

The prevailing consensus is that personal SRL’ s are better or more effective than energy-absorbing lanyards. This is not universally true, and in many cases it’s entirely false. Please be sure to consult with your manufacturer of choice or a competent distributor for specific details and assistance.

Why does a compact SRL have a separate shock absorber?

Many, if not most, compact or personal SRL’ s feature a separate or external tear-tape energy absorber. The simple reason for this is that these devices are expected to be small, lightweight, and economical. As a result, incorporating an internal rotary brake is a significant challenge, particularly when you factor in the need for a reserve line.

The most effective way to give the customer what they want, along with the energy-absorbing capability they need, is to use an energy absorber of this type.

What’s the difference between a vertical cable system and a rope system?

Aside from the obvious difference in materials, vertical cable systems are typically designed to be used as permanent or semi-permanent systems, usually with fixed ladders. Standard cable systems utilize a sleeved anchor that attaches to the cable. They’re usually connected to the user via loops or D-rings on the front of the harness. In the event of a fall, the sleeve locks to the cable and prevents the user from falling any further.

Rope systems can be used in a similar fashion, but offer the user greater freedom of movement. This is because they’re typically not used with fixed ladders or as permanent or semi-permanent systems. Rope systems use rope instead of cable. A “rope grab,” is affixed to the rope, and attached to the user either on the front of the harness (if the user is ascending or descending vertically) or “trails” behind the user. It’s attached via the back D-ring and often incorporates an energy absorbing device. The rope grab typically offers hands-free operation while ascending or descending in a straight vertical line. But it requires manual placement if the user is moving horizontally. This is common in roofing applications.

What type of harness should I use with a vertical system?

This is dependent upon the type of vertical system being used. Manufacturers of vertical systems will state recommendations or requirements for the type of harness to use when attaching to the system in question. In general, however, vertical systems fit into one of three categories:

Fixed Systems: Fixed systems use either a cable or a rail, as well as an anchor sleeve specific to the system. These systems often use the weight of the device to hold it into the “open” position, allowing it to traverse the cable or rail hands-free. In these cases, the device must be attached to the front of the harness, either to chest loops using a connecting device or to a chest-located D-ring. A harness that incorporates these features would be required to use such a system.

Temporary Systems: Temporary systems use a rope/rope grab combination. In this case, the user can attach the rope grab device to the front of the harness via chest loops and a connecting device, or to a chest-mounted D-ring. The user may also, however, attach the device to the dorsal D-ring of the harness. This should occur if it incorporates an energy absorber. A harness equipped with a dorsal D-ring and chest attachment points would be suitable for this application.

Semi-Fixed Systems: These systems forego the use of cable or rail, and utilize a stanchion attached to the top of a fixed ladder. They may also use an approved anchor point located above the top of the ladder. A self-retracting lanyard is affixed to the stanchion or anchor, and a tag-line is attached to the end connector of the SRL. The user pulls the cable out using the tag line, and then attaches the SRL connector to the dorsal D-ring of the harness. In this case, only a dorsal D-ring is required.

What does the new OSHA legislation say about fixed ladder systems?

Currently, under OSHA standard 1910.27, cages are required on ladders where the length of the climb exceeds 20 feet in height. In the new standard (1910.28) which takes effect on 11/19/2018, ladders will no longer be required to have fall protection until their height exceeds 24’. OSHA will also be requiring ladders installed after 11/18/2018 to have fall protection in the form of a Personal Fall Arrest System (PFAS) or Ladder Safety System which is not a cage. This last part is important, primarily due to the sheer volume of ladder cages that exist today. The good news for owners of existing caged systems is that they have until 2038 to comply with the new ruling.

The change in the standard is the result of OSHA better aligning the fixed ladder standard with the ANSI standard A14.3. This ANSI standard changed its fall protection height requirement from 20’ to 24’ in 1979.

Which is better - a vertical ladder stanchion system or a fixed ladder system?

The question itself is subjective, but there are some clear advantages to having a vertical ladder stanchion system versus a fixed ladder system.

Advantages of Vertical Ladder Stanchion Systems:

- Overhead anchorages coupled with an SRL means arrest distances less than 24”

- Inspection procedures are simple

- Standard dorsal D-ring harness will work

- System user training is much easier than other complex ladder safety systems

- Standard length kits are available in 30’, 50’, and 100’ lengths

- Existing SRL’s Can be used

Disadvantages of Traditional Fixed/Engineered Vertical Climbing Systems:

- Requires a harness with sternal D-ring

- Multiple users of a ladder either require their own cable grab, or waste time sending the unit back down, reducing worker productivity and efficiency