Ladder falls are routinely the 2nd leading cause of fatalities in industrial work. Even when the results don’t end in a fatality, they often result in temporary or permanent disability.

OSHA has taken notice of this and, in November 2016, passed new regulations for fall protection ladder safety.

Ladder cages are a solution of the past, and Ladder Safety Systems must be installed on every applicable ladder. This new standard will mean big changes over the next 20 years for industry facilities, worker safety, and the training required ensuring this standard is a success.

But which ladders need ladder safety systems, and what are the options?

This guide walks your through the ins and outs of fixed ladder safety

| X | Doesn't stop or prevent falls |

| X | Adds an additional collision hazard during a fall |

| X | Can cause dangerous and unpredictable tumbling |

| X | Makes incapacitated workers difficult to rescue |

| X | Gives false sense of security |

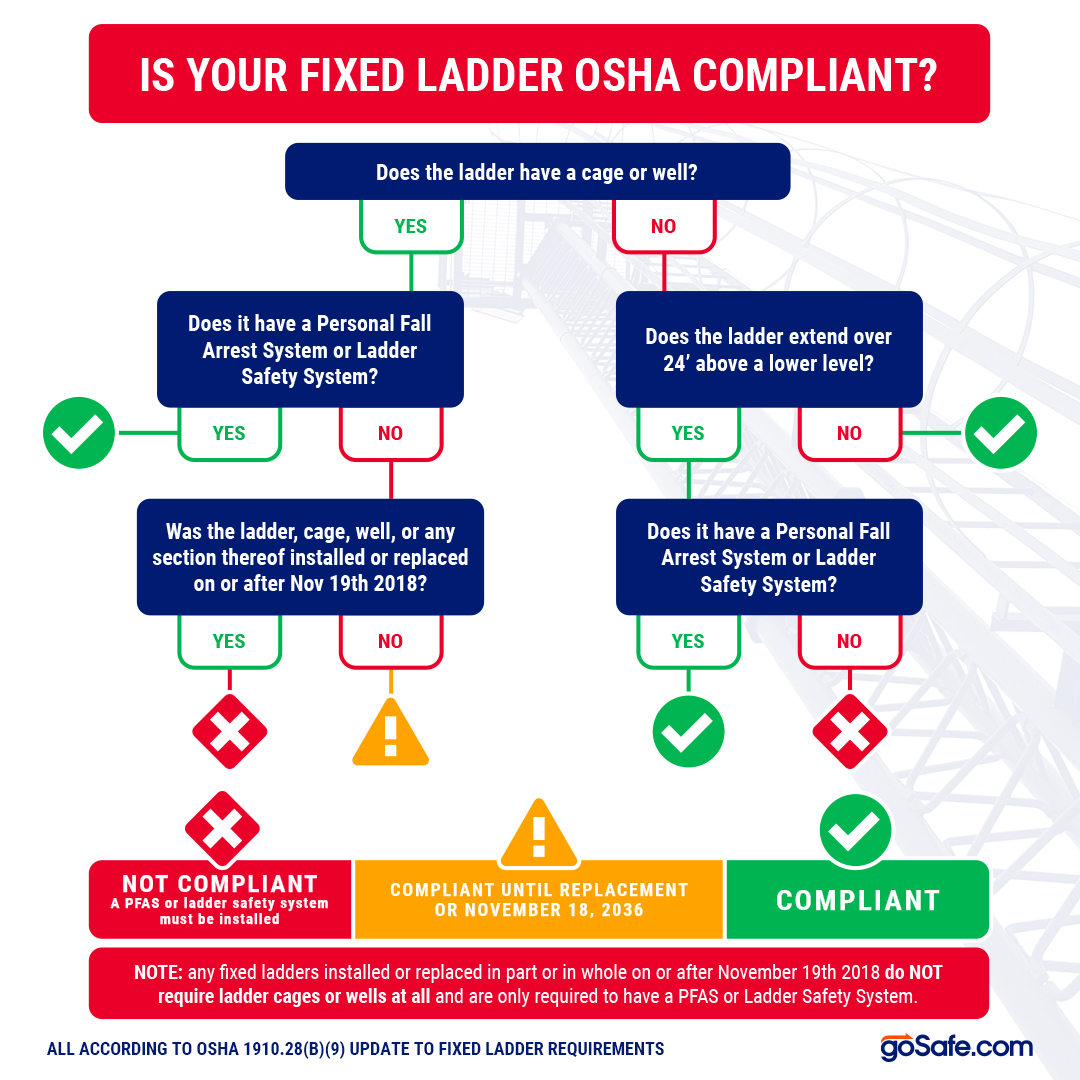

OSHA's requirements apply to all fixed ladders that extend 25ft above a lower level and have been installed or repaired in any capacity after November 19th 2018, with full adoption of ladder safety systems for every applicable ladder by November 18th, 2023

This means if your fixed ladder has a cage but has not been serviced since Nov 19th 2018, your ladder is still technically OSHA compliant... but not for long.

As soon as you repair or service any portion of that ladder, you are REQUIRED to outfit the ladder with a Ladder Safety System.

Likewise, all new ladders must also be equipped with a ladder safety system.

Whether your ladder has a cage or not is irrelevant, but we recommend removing them entirely and replacing them with a PFAS or Ladder Safety System to prevent collisions during a fall.

1910.28(b)(9)(i)

For fixed ladders that extend more than 24 feet (7.3 m) above a

lower level, the employer must ensure:

1910.28(b)(9)(i)(A)

Existing fixed ladders. Each fixed ladder installed before November 19, 2018 is equipped with a personal fall arrest system, ladder safety system, cage, or well;

1910.28(b)(9)(i)(B)

New fixed ladders. Each fixed ladder installed on and after November 19, 2018, is equipped with a personal fall arrest system or a ladder safety system;

1910.28(b)(9)(i)(C)

Replacement. When a fixed ladder, cage, or well, or any portion of a section thereof, is replaced, a personal fall arrest system or ladder safety system is installed in at least that section of the fixed ladder, cage, or well where the replacement is located; and

1910.28(b)(9)(i)(D)

Final deadline. On and after November 18, 2036, all fixed ladders

are equipped with a personal fall arrest system or a ladder safety

system

Ladder cages are the old guard of ladder safety, but fail to provide any level of real fall protection and doesn't stop a fall, it only guides it.

Vertical Climbing Systems offer a constant connection to the ladder through a rail or wire system that runs along the whole ladder and attaches to special harnesses and cable pullys.

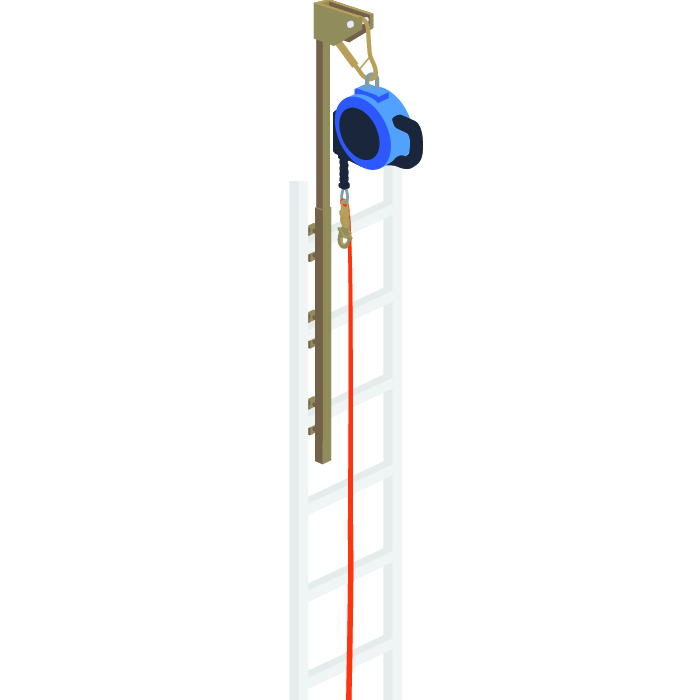

A Ladder Stanchion System secures a Self Retracting Lifeline at the top of the ladder with a rope grab, allowing a worker to pull it down and attach it to any harness with a dorsal D-Ring

| X | Requires Sternal D-ring |

| X | Custom, third party installation |

| X | Incompatible with step-thru style ladders |

| X | Long deceleration distances (up to 39”) |

| X | Specialized user training, risking human error |

| X | Susceptible to a variety of potential locking failures |

| X | Cable guides or rails hinder worker movement |

| X | Requires an entire set of new equipment |

| X | Requires secondary attachments for 100% tie-off |

| ✓ | Uses a Standard Dorsal D-ring |

| ✓ | Easy to install on nearly any ladder |

| ✓ | Supports step-thru ladders |

| ✓ | Arrest distances under 24” (With Skyloc II SRL) |

| ✓ | Works just like any standard SRL |

| ✓ | Uses an SRL for reliable locking. |

| ✓ | Installed at the top, no cables or rails |

| ✓ | Use existing SRLs or the robust Skyloc II® |

| ✓ | Provides 100% tie-off from ground to landing |

The Reliance Ladder Stanchion Systems provide the simplest and most effective ladder safety available that is perfectly scalable to ladders up to 100', providing an overhead anchorage from the top for full coverage.

By relying on an SRL at the top of the ladder, you bypass any need for complex installation of cables and rails, and eliminate the need for special harnesses with sternal d-rings, cable grabs, and special user training.

Compatible with nearly any ladder, SRL, and harness with a standard dorsal d-ring, the Ladder Stanchion System gives you the most effective fall protection available for nearly any application.

Installs on the top rungs of the fixed ladder with 3 bolt-on connection points, making it easy to install or reinstall with no cables, rails, or intermediary guides.

Compatible with nearly any standard ladder and harness with a dorsal D-ring, and compatible with step-thru ladders, with extendable roof-hatch options.

Because the system uses an overhead SRL, workers can use it just like any other anchor point with any harness with a dorsal D-ring.

Achieves sub-2ft arrest distances when paired with the high performing Reliance Skyloc II SRL, minimizing the risk of whiplash and collision.

REL6518G-1

Summary of OSHA Fixed Ladder Regulations and Fall Protection

OSHA's Walking/Working Surfaces regulations, specifically OSHA 1910.28(b)(9) for General Industry and 29 CFR 1926.1053(a)(19) for Construction, underwent significant updates in 2016, phasing out fixed ladder cages and wells as primary fall protection in favor of more effective systems. These regulations apply to any fixed ladder extending more than 24 feet (7.3 meters) above a lower level.

Key Compliance Dates and Requirements:

Why Ladder Cages Are Being Phased Out:

Cages and wells are not defined by OSHA as Personal Fall Arrest Systems or Ladder Safety Systems. They do not effectively arrest falls and can provide a false sense of security. In a fall, a cage can:

While existing cages or wells do not need to be removed if they don't interfere with the operation of a PFAS or ladder safety system, they are not a substitute for these modern solutions. New ladder projects over 24 feet do not require cages, which offers safety benefits, cost savings, and less worker restraint.

Approved Fall Protection Systems:

OSHA emphasizes two primary categories of effective fall protection:

Comparison of Advanced Systems:

Employers can choose between two main types of systems based on their needs:

Best Practices for Long-Term Compliance:

To ensure worker safety and compliance, employers should:

Prioritizing these proactive measures not only ensures adherence to regulations but also significantly enhances worker safety and prevents serious injuries or fatalities from falls.

goSafe's Blog Articles on this topic